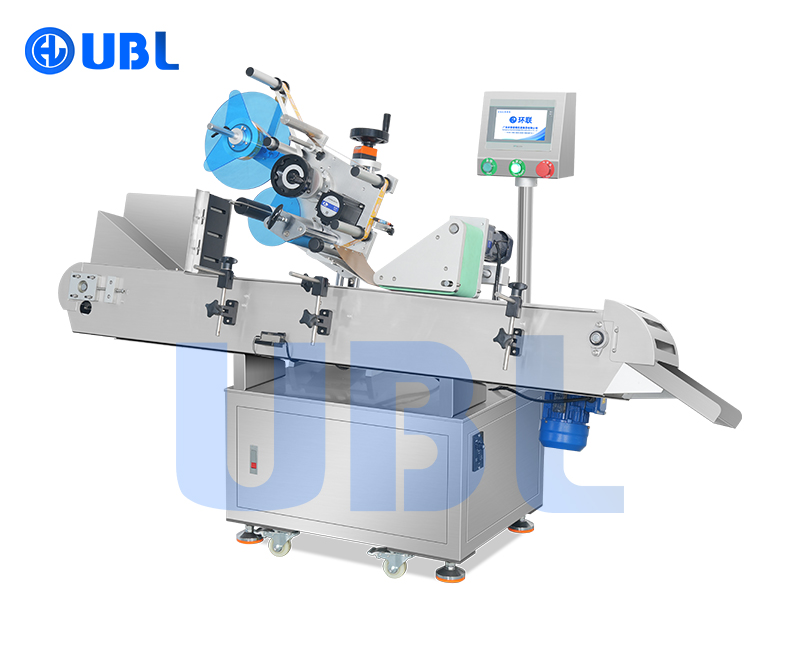

UBL automatic labeling machines are engineered for high-precision, stable, and efficient labeling across a wide range of product types, including flat pouches, boxes, bottles, cylinders, and irregular-shaped items.

Designed for industrial environments, they support top labeling, side labeling, wrap-around labeling, double-sided labeling, and corner sealing, meeting the diverse needs of packaging, logistics, cosmetics, food, electronics, and pharmaceutical industries.

Built with servo-driven labeling heads, smart sensor detection, and an industrial-grade PLC control system, UBL machines deliver consistently accurate label placement, fast changeover, and excellent long-term reliability.

UBL is CE-certified and holds more than 150 patents, with products exported to over 60 countries and regions including Germany, France, Singapore, India, and Mexico. Backed by advanced labeling automation technology and rigorous quality control, UBL has earned a strong global reputation as a trusted provider of high-precision labeling solutions.

Widely used across the food, beverage, pharmaceutical, personal care, electronics, and chemical industries, UBL labeling systems support flat-surface labeling, round-bottle labeling, and irregular-shape product labeling. They accommodate various applications including pressure-sensitive labeling, anti-counterfeit label application, and barcode/QR code labeling—helping manufacturers achieve efficient, precise, and fully automated labeling workflows.

● Industrial-grade PLC + touch-screen control

Siemens / Mitsubishi PLC control, user-friendly HMI interface, quick parameter adjustment, recipe storage, and intelligent alarm functions.

● Robust stainless-steel frame & modular structure

Heavy-duty stainless steel and aluminum alloy construction ensures durability in high-speed and long-hour production environments.

● Supports multiple labeling modesTop labeling / side labeling / wrap-around / double-sided / corner seal / L-shape / bottom labeling.

Compatible with various label materials and sizes.

● Stable performance for multi-SKU production

Fast changeover, adjustable labeling height/width, supporting flexible manufacturing and diverse product lines.

● Easy integration with upstream and downstream systems

Compatible with:

UBL specializes in delivering a full range of high-precision labeling automation solutions, offering ±0.5–1 mm labeling accuracy and high-speed performance of 3,000–12,000 pcs/hour. Our systems address labeling challenges across multiple industries, including food & beverage, pharmaceuticals, personal care, express logistics, and electronics.

Whether it’s traceability compliance for food packaging, precision labeling for pharmaceutical bottles, premium brand labeling for personal care products, or fast and accurate shipping-label application, UBL labeling machines provide the perfect fit. Through configurable functions—such as flat labeling, curved-surface labeling, and inline print-and-apply—our solutions adapt seamlessly to your production environment and packaging requirements

UBL-T-300 Fully Automatic Flat Surface Labeling Machine

UBL-T-304 Fully Automatic Top & Bottom Surface Labeling Machine

UBL-T-118 Semi-Automatic Flat Surface Slide Platform Labeler

UBL-T-106 Benchtop Fully Automatic Flat Surface Labeling Machine

UBL-T-101 Benchtop Flat Surface Labeling Machine

UBL-T-301 Fully Automatic Card Labeling Machine

UBL-T-401 Fully Automatic Positioning Round Bottle Labeling Machine

UBL-T-400 Fully Automatic Round Bottle Labeling Machine

HL-T-402 Horizontal Round Bottle Labeling Machine

UBL-T-209 Benchtop Round Bottle Positioning Labeling Machine

UBL-T-208 Benchtop Round Bottle Labeling Machine

UBL-T-200 Semi-Automatic Round Bottle Labeling Machine

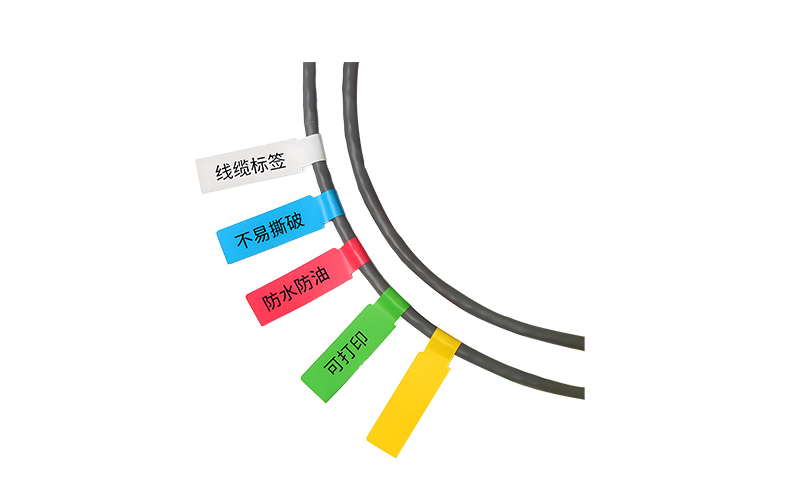

The UBL-T-107 is a high-performance, purpose-built folding labeling machine designed with advanced wrap-around folding technology. Engineered for cylindrical and elongated products, this system uses customizable fixtures to ensure precise, efficient, and stable fold-over label application—meeting the identification needs of multiple industries and product types.

■ Exceptional Adaptability

Configurable with custom fixtures to perfectly fit a wide range of products, including wire and cable, plastic tubing, hangers, cutlery (knives/forks), lollipops, jelly sticks, disposable plates and bowls, and more.

■ Precision Fold-Over Labeling

Built with a high-accuracy mechanical structure and advanced control system, the UBL-T-107 ensures perfectly wrapped fold-over labels with ±0.5–1 mm labeling accuracy.

■ High Flexibility & Efficiency

Supports a wide label size range (fold-over width 40–130 mm) with output speeds up to 1,200 pcs/hour, significantly improving production throughput.

■ Durable, Industrial-Grade Construction

Compact and robust (650 × 800 × 1100 mm) with low power consumption (0.25 kW). Engineered for continuous industrial operation to ensure long-term, reliable performance.

The UBL full-automatic multi-function labeling machine is engineered for high flexibility and precision, making it suitable for a wide range of flat, square, and round container labeling applications.

Equipped with a versatile 8-axis adjustment system, the labeling head can be finely tuned—up/down, left/right, front/back, and angle adjustments—ensuring quick setup and highly accurate positioning for every product type.

This system supports single-side and double-side labeling for flat or square bottles, and features an integrated positioning-type round bottle labeling module.

This allows the machine to not only apply simultaneous dual-side labels on flat containers but also perform 360° wrap-around labeling or apply one or two labels (front & back) on round bottles with precise orientation control.

Designed for maximum adaptability, the machine is widely applied across industries handling flat or square containers, including:

Lubricants & automotive chemicals

Car cleaning agents & windshield fluid

Laundry detergent & household chemicals

Chili oil, sauces, and other food bottles

With its robust structure, high-speed servo control, and flexible configuration, this multi-function labeling system delivers stable performance, high accuracy, and exceptional convenience for diverse packaging environments.

Here you’ll find clear answers to all key questions about labeling machine accuracy, industry compatibility, technical standards, and automation capabilities.

With more than a decade of specialization in labeling automation, UBL focuses on the development and manufacturing of high-precision flat labeling, round-bottle labeling, and inline print-and-apply systems.

Our solutions serve a wide range of industries—including food & beverage, pharmaceuticals, personal care, e-commerce logistics, and electronics—providing both standalone machines and fully integrated labeling systems.

This FAQ hub is designed to help you confidently evaluate and select the right labeling equipment. Choosing a reliable and compliant labeling machine is essential for reducing operating costs, improving efficiency, and ensuring consistent label quality.

In addition to machine performance, this section also covers topics such as label material compatibility, production line integration, and industry-specific applications.

Whether your needs involve food packaging, pharmaceutical traceability, shipping labels, or cosmetic branding, UBL offers labeling solutions tailored to your exact production environment and requirements.

UBL machines support a wide range of label types and materials, including:

Standard pressure-sensitive labels

Transparent / clear labels

Anti-counterfeit and security labels

Barcode and QR code labels

Wrap-around, dual-side, and corner labels

Fold-over / flag labels for cables and tubes

Heat-resistant, cold-storage, and waterproof label materials

Paper, PP, PET, PVC, PE, synthetic films

Label size compatibility varies by model, and custom configurations are available for non-standard label formats.

UBL labeling systems are widely used in:

Food & beverage (traceability, nutrition labels, brand labels)

Pharmaceuticals & healthcare (GMP/FDA-compliant labeling, batch & QR traceability)

Personal care / household chemicals (cosmetics, detergents, daily chemicals)

E-commerce logistics (shipping labels, pouch labels, tracking labels)

Consumer electronics (adapters, small devices, modules, batteries)

Industrial products (cables, tubes, components)

UBL is designed for both high-volume automated lines and flexible multi-SKU production.

Depending on the model, UBL labeling machines comply with:

CE Certification

ISO industrial safety standards

Food-grade and pharma-grade design principles

GMP-compliant operation requirements

Industry-specific electrical and EMC safety guidelines

Materials and electrical components are sourced according to international quality standards.

Working principle:

Automatic product feeding → label detection → servo-driven label dispensing → synchronous label application → pressure-roll finishing → inspection & rejection of defective products.

UBL technical advantages:

±0.5–1 mm labeling accuracy

High-speed servo control system

Siemens/Omron industrial-grade PLC

Modular design for multi-mode labeling

Fast format changeovers for multi-SKU lines

Brushless motors and stable tension control

Optional print-and-apply integration

Intelligent label sensor for transparent labels

These ensure stable, repeatable, and high-quality labeling even for challenging product shapes.

Typical supported ranges (custom options available):

Label width: 10–150 mm (model-dependent)

Label length: 20–300 mm

Round bottle diameter: 15–120 mm

Flat bottle thickness: 10–80 mm

Speed: 3,000–12,000 pcs/hour depending on product size and label type

Special shapes (oval, irregular bottles, tubes) can be adapted through customized fixtures.

Most UBL models support tool-free adjustment, and format changeovers typically take 5–15 minutes, ideal for multi-SKU industries like cosmetics or electronics.

Industrial-grade servo motors

Rigid stainless-steel frame

High-stability label tensioning

Automatic calibration & detection

24/7 continuous running capability

UBL machines are designed for high-volume industrial environments.

Absolutely. UBL specializes in:

Non-standard fixtures

Special-shaped bottle labeling

Multi-head labeling systems

Wrap-around + front/back combination labeling

Cable flag labeling

Ecommerce shipping print-apply labeling

Custom engineering is one of UBL’s strengths.

We provide solutions across a wide range of industries. To learn more, please click below to view our case studies.

UBL offers a complete automatic packaging solution for the food industry through its advanced carton folding machines and cartoning machines.

In the cosmetics industry, packaging is more than just protection — it represents brand value and customer experience.

Alcohol is one of the most common beverages in everyday life, but among the many liquor suppliers, how can a brand truly stand out?

+86 13602308576

cy@huanlianauto.com

No. 7 Yinhu Road, Sangyuan Industrial Park, Dongcheng Street, Dongguan City, Guangdong Province, China

Guangdong Huanlian intelligent Packaging Group Co., LTD

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back catalog and price list to you ASAP!

Your project will meet a right solution with UBL.