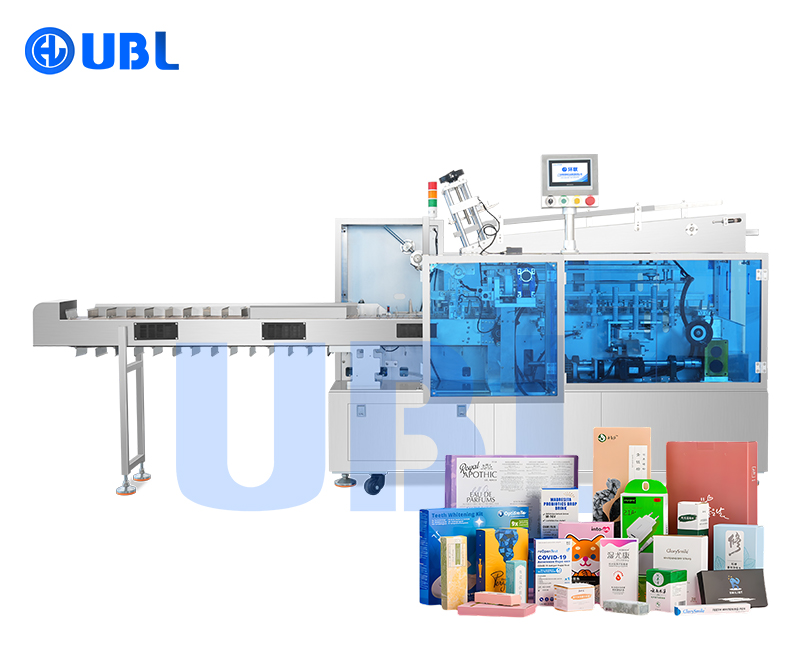

Everything you need to know about carton folding machines, cartoning machines, labeling machines, and other automated packaging equipment is right here.

With years of experience in the automated packaging equipment industry, UBL focuses on the research, development, and manufacturing of folding machines, cartoning machines, labeling machines, and related equipment. This Q&A portal is designed to provide you with a comprehensive and in-depth resource for evaluating automated packaging solutions, helping you make informed decisions when selecting equipment.

The core goal of this section is to make it clear that purchasing reliable, qualified automated packaging equipment is key to reducing costs and increasing efficiency. Conversely, acquiring substandard equipment can lead to a series of negative consequences, such as:

Rising labor and technical maintenance costs

Frequent downtime, production line adjustments, or additional equipment investment due to insufficient reliability

Production interruptions that seriously impact delivery schedules and corporate reputation

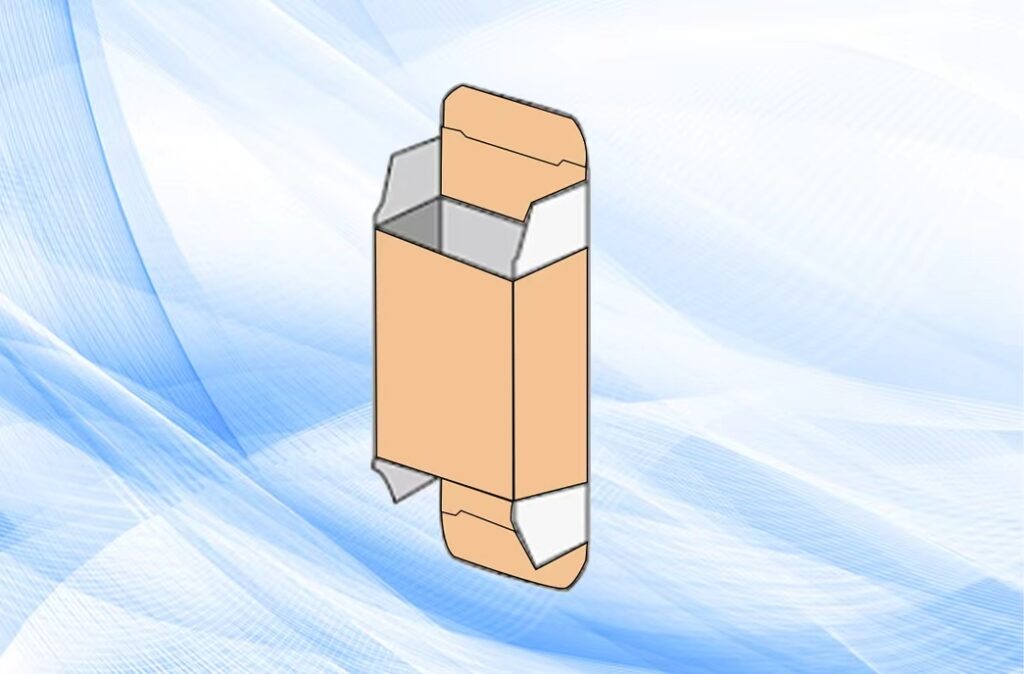

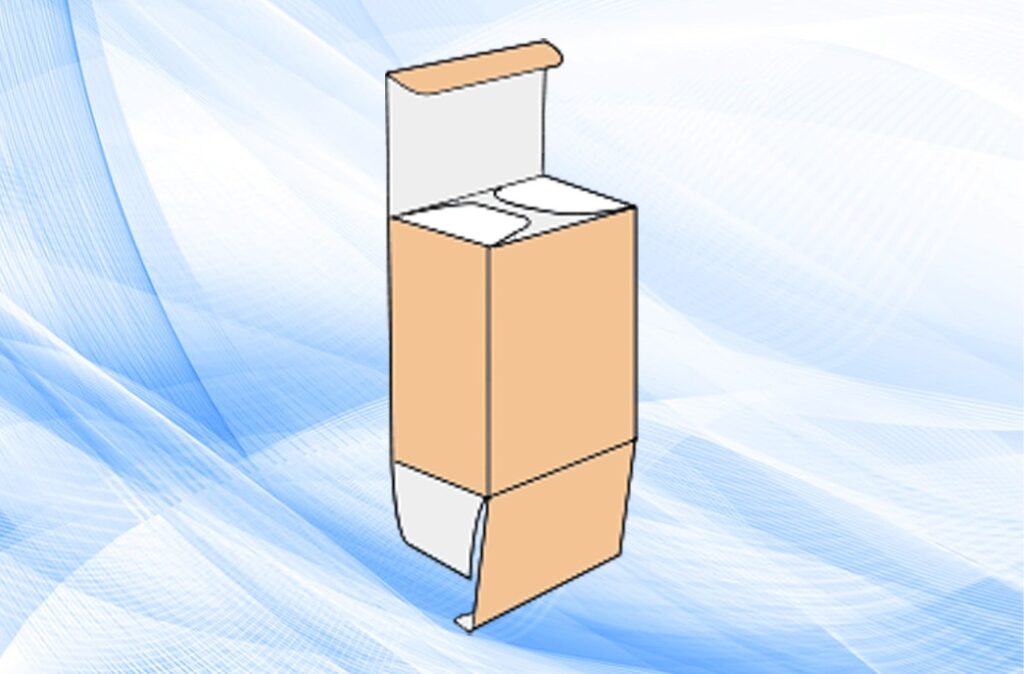

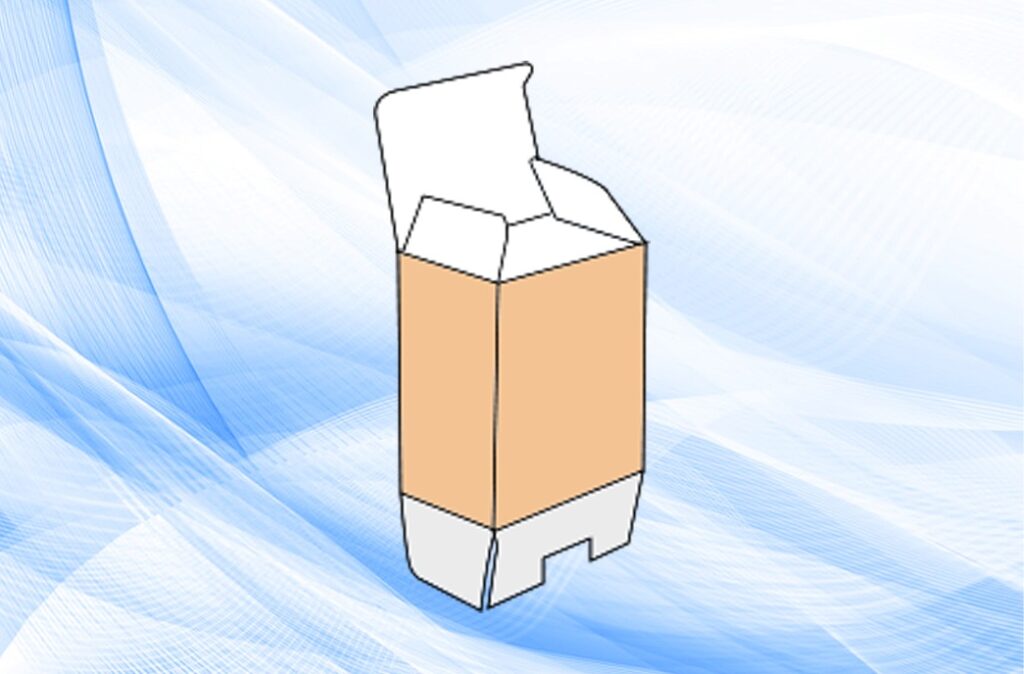

Beyond the equipment itself, this Q&A portal also covers related topics such as packaging materials (e.g., glue-sealed cartons, snap lock bottom cartons, tuck-tab cartons), production line integration, and industry applications. You can accurately match the most suitable automated packaging solution according to your product specifications and production requirements.