Everything you need to know about carton folding machines, labeling systems, and automated packaging equipment is right here.

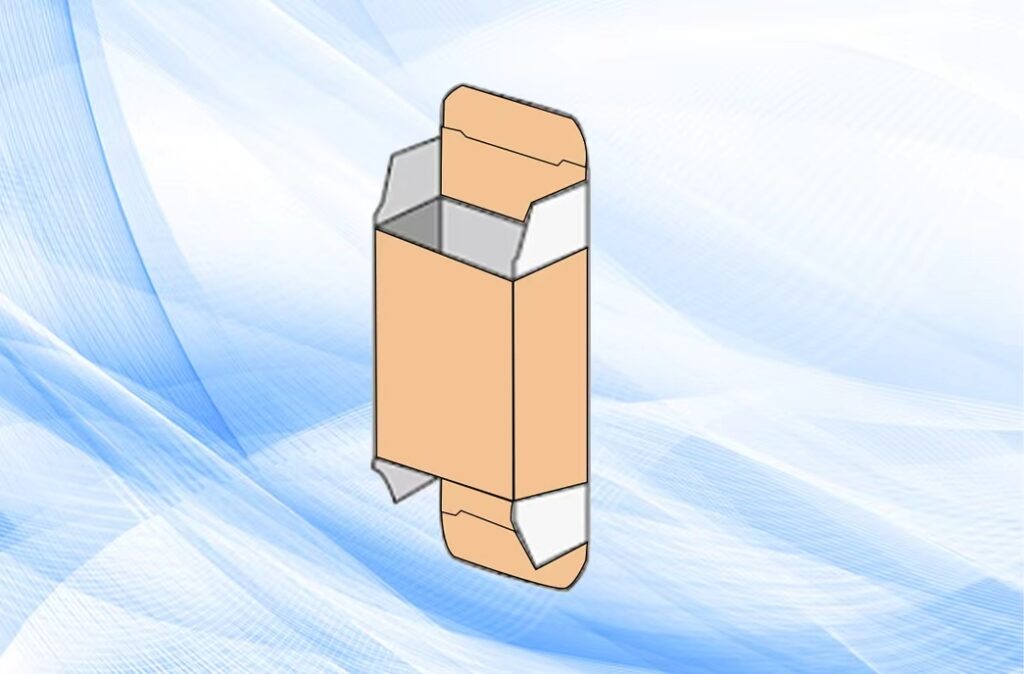

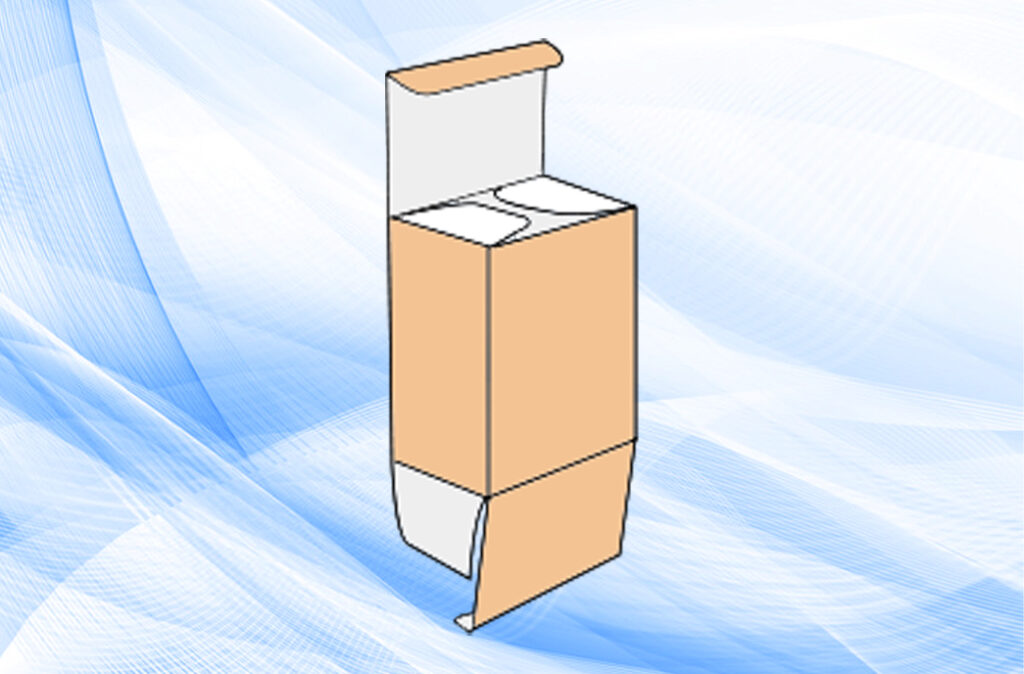

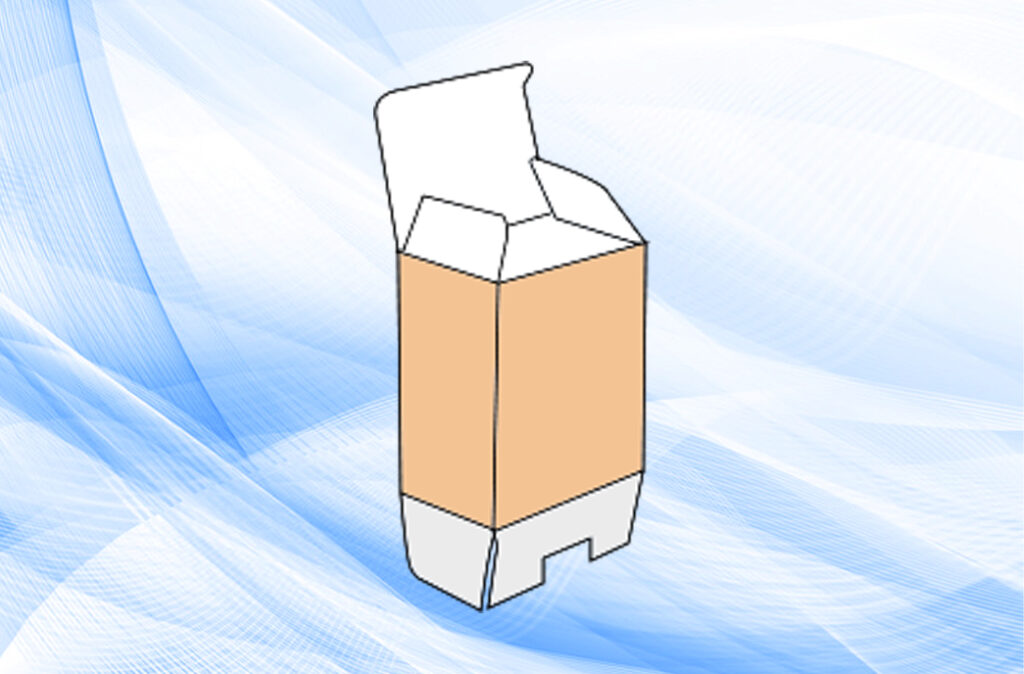

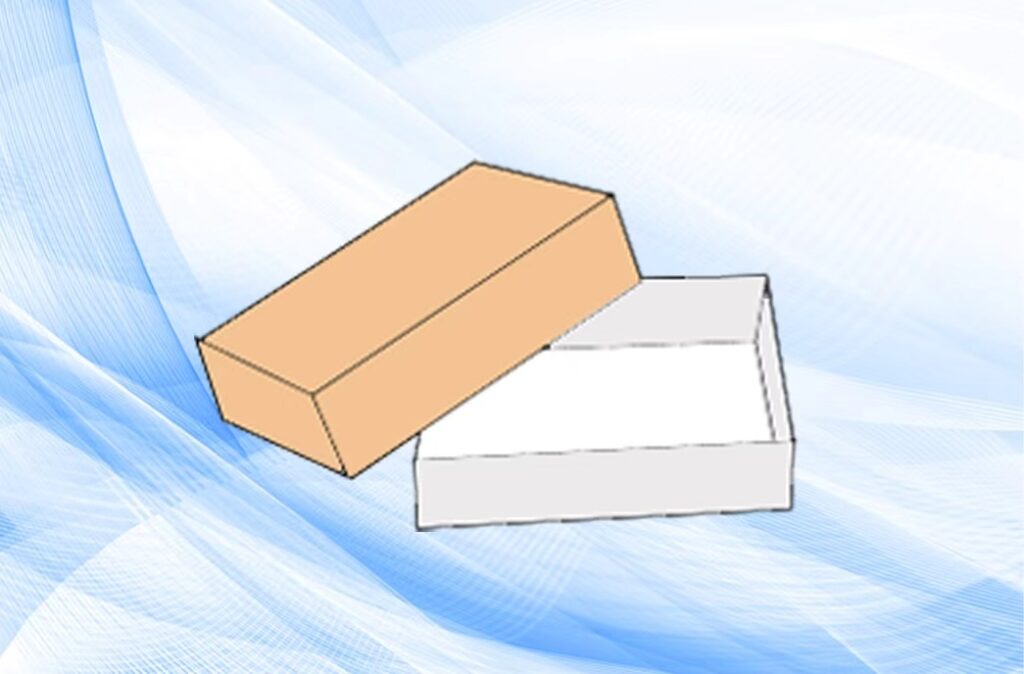

With decades of experience in the folding and packaging automation industry, UBL specializes in the R&D and manufacturing of high-precision folding machines for various box types — including Snap Lock Bottom boxes, Mailer Boxes, Glue-Sealed Cartons, Tuck End Boxes (STE/RTE), and Rigid Boxes with Lids.

This Q&A Portal is designed to provide a complete guide for evaluating and selecting carton folding equipment, helping you make informed decisions for your production line. Our goal is simple: to show that investing in reliable, qualified folding machines is the key to reducing costs, increasing efficiency, and improving packaging quality.

Choosing substandard machinery, however, can result in serious setbacks — including:

Beyond equipment performance, this portal also explores related topics such as packaging material compatibility, line integration, and industry-specific applications. Whether you’re packaging cosmetics, food, pharmaceuticals, or e-commerce products, you’ll find the right UBL folding solution tailored to your specific box structure and production requirements.