Automatic cartoning machine for small boxes have become an absolute must-have in the global competitive race of high-volume industries such as food, pharmaceuticals, and cosmetics. For enterprises striving to stand out, the core lies in improved packaging efficiency—and the critical technical backbone behind this high performance is precisely the automatic cartoning machine for small boxes equipped with advanced servo technology.

The Critical Role of the End-of-Line Cartoning System

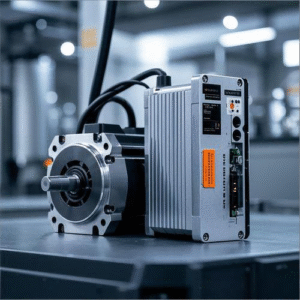

Precision and Speed: Servo Cartoner machine

Key advantages of servo technology in cartoning include:

- Flexibility: Recipes for different box sizes can be stored digitally, allowing operators to switch between products with the push of a button, drastically reducing changeover time from hours to mere minutes.

- Reduced Maintenance: By replacing complex mechanical components with electronic motion control, the number of wear parts is significantly reduced, leading to lower maintenance costs and higher uptime.

- Smooth Acceleration: Servo drives enable smooth, controlled acceleration and deceleration, which is crucial for handling fragile products like small food boxes without spillage or damage.

Enhanced Stability And Consistency For Small Box Packaging

Beyond speed and flexibility, servo-driven cartoning machines deliver a level of process stability that traditional systems simply cannot match. Because each axis operates independently with real-time feedback, the machine can automatically compensate for minor variations in carton quality, board stiffness, or product positioning.

This is particularly critical for small box cartoning, where lightweight cartons are more susceptible to deformation, tipping, or misfeeds. Servo control ensures consistent carton squareness, precise flap folding, and reliable sealing—resulting in fewer rejects and a more professional final appearance on the shelf.

Ready To Upgrade Your Small Box Cartoning Line?

If you’re evaluating an automatic cartoning machine for small boxes or considering a servo cartoner to improve speed, flexibility, and line stability, now is the right time to take the next step.

Our engineering team offers:

-

📊 Free production line assessment based on your actual carton size, product type, and target output

-

⚙️ Machine selection consultation to match the right servo cartoning solution to your application

-

💰 ROI and efficiency analysis to help you justify automation investment with real data

👉 Click here to request a quotation or schedule a cartoning line evaluation

Or leave a message below—our specialists will get back to you with a tailored solution.