Many manufacturers think upgrading packaging machines means replacing hardware (motors, frames, etc.). But true flexible packaging relies on two overlooked “software” factors: control system programming flexibility and user-friendly operating interfaces—these determine fast SKU switching, reduced setup time, and less costly downtime.

Why Software Flexibility Defines a Modern Packaging Machine

With SKU changes happening weekly or daily, a flexible packaging machine must handle varying bag sizes, materials, speeds and labeling logic—no sensor rewiring or core logic overhauls required.

Control System Programming Flexibility

A fully flexible line requires a PLC system designed for fast parameter changes, modular code, and a clear logic structure.

What to Look For:

-

Recipe storage for different products

-

Modular programming blocks (filling, sealing, labeling)

-

Quick adjustment parameters (speed, timing, feeding)

-

Remote diagnostics to troubleshoot without opening cabinets

A poorly programmed system means every product change requires an engineer onsite. A good system lets operators load recipes with a click.

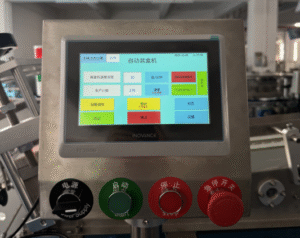

User-Friendly HMI (Human-Machine Interface)

Even a powerful control system is useless if operators can’t use it confidently. The HMI is the face of your packaging machine.

What Good HMI Design Means:

-

Clear layout and visual icons

-

Guided setup workflow

-

Real-time alarm explanation

-

Video demo or step-by-step prompts

-

Multi-language interface

-

Technician and operator permission levels

A smart HMI reduces training time, avoids operating mistakes, and makes new staff productive faster.

Hardware Matters—but Software Drives Flexibility

Motors, sensors, and frames determine stability, but the programming logic and interface design decide how fast you can adapt. In small-batch, multi-SKU environments—such as cosmetics, snacks, coffee, pet food, or nutraceuticals—the difference can be hours saved per changeover.

If you’ve found hidden software challenges in your packaging machine, or you’re exploring better ways to manage frequent product changeovers, share your experience in the comments—your insights can help others facing the same issues.