The E-commerce Packaging Bottleneck: Why Manual Bagging Fails

In today’s e-commerce fulfillment environment, relying on an automatic bagging machine is no longer optional — it’s the baseline for controlling labor costs and maintaining packaging consistency. Many warehouses still depend on 6–8 manual packers per line, with labor consuming over 50% of total packaging expenses. Manual bagging also introduces quality risks: wrinkled bags, poor seals, and handling errors that can push scrap rates to 8–10% during peak seasons. Industry research shows that inefficient packaging processes are a key driver of fulfillment delays and rising operational costs【1】. When order volume surges, these small inefficiencies quickly turn into late shipments, customer complaints, and a damaged brand experience.

The solution is not hiring more people, but deploying a dedicated automatic bagging machine designed for high-volume e-commerce fulfillment.

Automatic Bagging Machine: Features and Functions

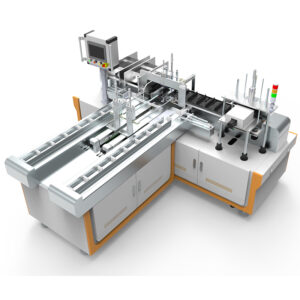

The UBL Automatic Bagging Machine is engineered to transform your packaging line from a cost center into a strategic asset. Key features ensure reliability and speed:

- Automatic Bag Feeding Module: Precisely supplies pre-made bags, eliminating the time wasted on manual bag handling.

- Vacuum Bag Opening System: Ensures a near-perfect 99% open rate without manual adjustment, minimizing downtime.

- Infrared Product Positioning: Guides products accurately into bags, paired with heat sealing for second-level sealing speed and consistency.

- PLC-Controlled Workflow: Synchronizes all steps for a seamless, fully automated operation, reducing the need for constant human oversight.

Three Key ROI Advantages: The Strategic Shift to Auto Bagger

For warehouse owners and purchasing managers, the decision to invest in an auto bagger is driven by clear, quantifiable returns:

- Labor Cost Reduction: One packaging automation equipment unit can replace 3–5 workers. Based on an average monthly wage of $2,700, this translates to a direct saving of $8,100–$13,500 per month in labor costs. This is the most immediate and significant ROI factor.

- Material Waste Reduction & Sustainability: Advanced automatic film control reduces plastic use per bag by 15–20% and lowers the scrap rate to under 3%. For large-scale operations, this material efficiency can save over $100,000 annually in material costs, aligning with global sustainable packaging goals.

- Increased Operational Efficiency: The machine’s speed accelerates order turnaround, reducing shipment times by up to 20%. This minimizes potential customer complaint compensation due to delays and significantly improves the overall efficiency of your order fulfillment process.

For e-commerce warehouses and 3PL providers, the UBL Automated Bagging Machine is not just an equipment upgrade—it’s a strategic solution to optimize your cost structure. By achieving a 40% reduction in packaging costs, including direct labor savings and efficiency-driven hidden gains, your warehouse can realize a dual breakthrough in cost reduction and quality improvement in a competitive logistics environment.

For a complete solution, consider integrating our labeling machines. Click here to learn more about our labeling solutions.

【1】How automation is reshaping warehouse operations – McKinsey & Company