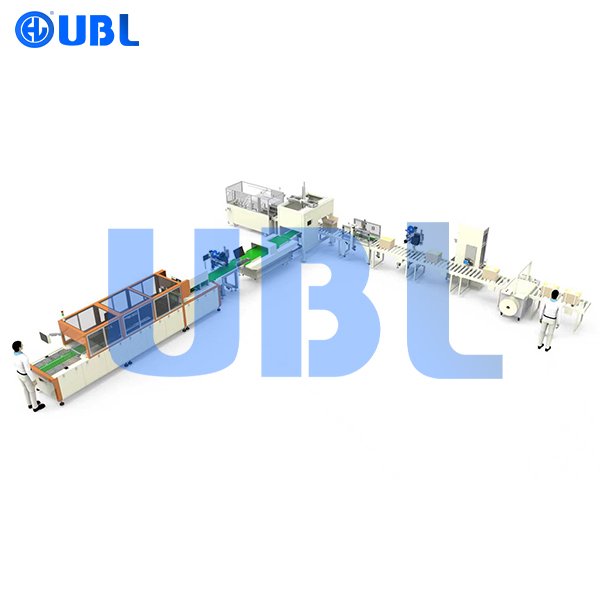

With the continued growth of the e-commerce apparel market, platforms like Amazon, eBay, and Zalando have witnessed a sharp order surge — yet many large and medium-sized apparel enterprises are trapped in a “packaging bottleneck” due to disconnected manual sorting, folding, bagging, and labeling processes. This leads to inefficiencies, higher risks of labeling errors or irregular folding, and ultimately harms logistics efficiency and customer experience. To tackle this pain point, UBL has launched its Clothing Folding and Express Packaging Production Line, featuring “manual feeding + fully automated process integration”: after workers place garments into the input tray, the system takes over to automatically fold clothes (suitable for T-shirts, jackets, etc.) with precision, place them into packaging bags, apply product information labels, seal the inner bags, transfer them to express shipping bags, and affix customer information labels while sealing — creating a seamless workflow.

The production line’s core strength lies in its “zero-workflow break”: only one worker is needed for feeding, cutting labor costs by up to 70% through full post-feeding automation. It also offers flexible adjustments for different folding specifications, labeling positions, clothing sizes, and shipping bag types, eliminating frequent reconfigurations and saving time. For large and medium-sized enterprises, this solution not only meets peak-season order demands but also ensures logistics accuracy via “dual labeling” (product + customer information), reducing mis-shipments and missed deliveries. By eliminating the need for temporary workers and repetitive process checks, businesses achieve cost reduction, efficiency improvement, and enhanced customer experience — gaining a competitive edge in the fiercely contested e-commerce apparel market.

+86 13602308576

cy@huanlianauto.com

No. 7 Yinhu Road, Sangyuan Industrial Park, Dongcheng Street, Dongguan City, Guangdong Province, China

Guangdong Huanlian intelligent Packaging Group Co., LTD

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back catalog and price list to you ASAP!

Your project will meet a right solution with UBL.