This machine is designed to enhance throughput, reduce labor costs, and ensure consistent bagging quality across high-volume production lines.

The biggest advantage of a fully automatic bagging machine is efficiency. A well-configured unit can increase production output by 40% to 70% compared with manual work, while delivering more consistent product quality and a lower rejection rate. Depending on the model and bag format, production capacity can reach 1,500 to 1,800 bags per hour, running 24 hours a day with stable performance. While it would take multiple workers to reach the same output, the machine delivers steady, repeatable results without fatigue, shift changes, or human error.

From a financial perspective, the return on investment is very straightforward. By replacing 2 to 6 operators per shift and ensuring continuous production, many companies are able to recover their full equipment investment within six months. After that, every hour of production goes directly to profit. At the same time, a bagging machine reduces labor dependence, stabilizes production schedules, and helps factories solve the growing shortage of skilled workers—especially during peak seasons.

An automatic packaging machine is an advanced piece of equipment designed to automatically open, fill, and seal bags with high precision and consistency. It eliminates the need for manual packaging, significantly reducing labor costs while improving production efficiency and packaging uniformity. These machines are essential in industries where product protection, hygiene, and efficiency are critical — such as medical supplies, food processing, and consumer goods manufacturing.

UBL’s automatic bagging solutions are widely used across garment, textile, medical, and electronics packaging sectors. From folding and bagging T-shirts, surgical gowns, and dustproof suits to sealing medical garments or blankets, UBL machines deliver clean, airtight, and professional packaging results. The system supports multi-size memory settings, allowing quick changeovers for different product dimensions. With advanced automation, stable sealing quality, and reduced downtime, UBL bagging machines help businesses increase throughput, maintain consistent packaging quality, and meet global efficiency standards — making them an ideal choice for modern automated production lines.

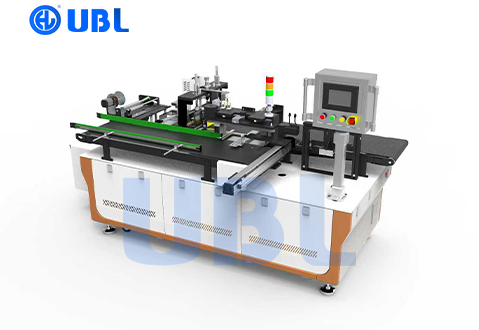

UBL fully automatic bagging machine is an integrated smart packaging system that combines automatic bag feeding, bagging, and sealing in one process. It is compatible with various bag types, including premade bags, gusset bags, punched bags, and self-adhesive tear-strip bags. Powered by advanced servo control and a modular mechanical structure, this series is ……

The packaging industry is accelerating toward sustainable packaging as it faces unprecedented pressure from stricter environmental regulations and rising material costs. Reducing plastic consumption and cutting waste is no longer optional — it’s now essential for compliance, brand responsibility, and long-term competitiveness. Transitioning to sustainable packaging by optimizing packaging design……

In the fast-paced world of e-commerce fulfillment, inefficient manual bagging processes lead to high labor costs, inconsistent packaging quality, and delayed order fulfillment. Huanlian’s automated bagging machines—integrating automatic bag feeding, opening, sealing, and product loading into a seamless workflow—are engineered to solve these pain……

Choosing the right bagging machine is essential for keeping your packaging line fast, stable, and cost-efficient. Many slowdowns or quality issues come from buying a machine that doesn’t match production needs. Before investing, confirm these eight key parameters to avoid future downtime.

The UBL Fully Automatic Envelope Tear-Tape Bagging Machine is an all-in-one automated solution that integrates film feeding, bag making, bag insertion, and sealing.

It is specifically designed for efficient packaging of envelopes, document pouches, gift sets, and similar products.

By combining core modules such as automatic film feeding, card feeder automatic supply, product transport, automated push-and-bag insertion, bag forming, and sealing, this machine achieves fully unattended operation—from raw film to finished product—providing precise, high-efficiency packaging solutions across daily essentials, educational materials, electronics, and medical industries.

Covers film feeding, bag making, product insertion, sealing, and finished product output, replacing manual labor and boosting production efficiency to 900–1200 PCS/hour while significantly reducing labor costs and error rates.

All components are designed for high-speed, high-efficiency operation. The machine features a simple, easy-to-maintain layout, with intuitive adjustment and maintenance procedures, capable of stable long-term operation in continuous production scenarios.

Supports vacuum sealing, UV printing, heat sealing, online labeling/printing, and other custom features, flexibly adapting to specialized industry needs such as anti-counterfeit packaging for premium gift sets or labeling for document pouches.

UBL’s high-speed gusseted bagging machine is engineered for precise, efficient, and fully automated bagging of various products into pre-made gusseted bags.

Equipped with a servo-driven motion system and Siemens PLC + touchscreen interface, the machine ensures smooth bag feeding, accurate insertion, and secure sealing with minimal downtime.

Key performance features include:

Speed: 30–50 bags per minute (depending on bag size and product type)

Precision: Servo-controlled bag opening and insertion guarantees consistent placement and fold alignment

Construction: Stainless steel frame compliant with hygiene standards for food, medical, and consumer products

Automation: Automatic fault detection, tool-free changeover for different bag sizes, and easy integration into existing production lines

Applications: Ideal for food, beverage, cosmetics, electronics, and medical products, providing high productivity while maintaining packaging quality.

This machine is designed to enhance throughput, reduce labor costs, and ensure consistent bagging quality across high-volume production lines.

UBL’s fully automatic punch and bagging machine is designed to efficiently handle products into pre-made bags with integrated punching, opening, and insertion processes.

The system combines servo-driven mechanisms with a Siemens PLC control platform, ensuring high-speed, precise, and reliable operation.

Key features include:

High Efficiency: Designed for 30–50 bags per minute, depending on product and bag specifications

Precision Punching & Bagging: Automatic punching, bag opening, and insertion guarantee accurate alignment and consistent packaging quality

Robust Construction: Stainless steel frame with hygienic design suitable for food, medical, and consumer products

Automation & Flexibility: Easy tool-free changeover for different bag sizes, real-time fault detection, and seamless integration into automated production lines

Versatile Applications: Ideal for food, cosmetics, hardware, and pharmaceutical products, enhancing productivity while maintaining consistent bag sealing quality

This machine streamlines bagging workflows, reduces manual labor, and supports high-volume production with stability and precision.

The UBL Four-Corner Cut & Bagging Machine is an intelligent automated packaging solution that integrates corner cutting and bagging in a single workflow.

Equipped with a high-precision servo control system and robust mechanical design, it automates the entire process from corner cutting to bagging.

This machine is ideal for electronics, medical, personal care, and food industries, helping enterprises build highly efficient and accurate packaging production lines.

Combines four-corner cutting and bagging operations, eliminating manual handling and boosting production efficiency. Compatible with pre-made bags, laminated bags, and other types for versatile packaging needs.

Servo-driven system ensures corner cutting accuracy of ±0.1mm and precise bag alignment, delivering neat, structurally sound packaging that enhances brand presentation.

Simple, well-organized structural design allows for easy adjustment and maintenance, reducing long-term upkeep costs and ensuring stable operation.

Adjustable to various product and bag sizes, supporting diverse industry-specific packaging requirements.

Q1: What is a bagging machine and how does it work?

Answer:

A bagging machine is an automated packaging device designed to fill and seal bags with products efficiently and consistently. UBL bagging machines integrate high-precision servo-driven mechanisms, intelligent control systems, and modular construction to ensure stable operation and high output. These machines are capable of handling a wide range of bag types including pre-made bags, gusseted bags, four-corner cut bags, and adhesive-sealed bags. They significantly reduce labor costs while improving packaging accuracy, consistency, and hygiene compliance, making them ideal for industries such as food, electronics, medical supplies, cosmetics, and consumer goods.

Q2: What industries are suitable for UBL bagging machines?

Answer:

UBL bagging machines are widely applied across multiple industries, including:

Food & Beverage: Snacks, confectionery, grains, and packaged liquids.

Medical & Healthcare: Sterile medical kits, surgical disposables, and pharmaceuticals.

Electronics & Components: Small parts, modules, and accessories requiring protective packaging.

Cosmetics & Personal Care: Sample kits, cosmetic sets, and hygiene products.

These machines provide consistent sealing, precise bag alignment, and optional coding or labeling, meeting industry-specific standards and compliance requirements.

Q3: What are the main advantages of UBL bagging machines?

Answer:

High Efficiency: Capable of 30–50 bags per minute depending on bag size and machine configuration.

Precision Control: Servo-driven mechanisms ensure accurate bag filling, positioning, and sealing.

Hygienic & Robust: Constructed from high-strength stainless steel, meeting food-grade and medical hygiene standards.

Modular & Flexible: Supports multiple bag types (gusseted, pre-made, four-corner cut, adhesive-sealed) and can be integrated with upstream and downstream production lines for full automation.

Q4: Can UBL bagging machines integrate with existing production lines?

Answer:

Yes, UBL bagging machines are designed for seamless integration. With intelligent PLC control and servo-driven operation, they can synchronize with filling machines, labeling systems, and cartoning equipment, creating a fully automated packaging line. This reduces manual handling, minimizes errors, and boosts overall line efficiency.

Q5: Are there optional features for specialized packaging needs?

Answer:

UBL bagging machines offer multiple optional features:

Coding & Labeling: Inkjet, thermal printing, or label application for traceability and branding.

Bag Size Adaptation: Quick-adjust systems and optional bag tooling allow for different bag sizes and shapes.

Line Connectivity: Remote monitoring, predictive maintenance alerts, and multi-device integration.

These options make the machines suitable for high-end, customizable packaging applications across industries.

We provide solutions across a wide range of industries. To learn more, please click below to view our case studies.

The E-Commerce Apparel Market Continues to Grow, but Major Apparel Companies Face “Packaging Bottlenecks”

In the cosmetics industry, packaging is more than just protection — it represents brand value and customer experience.

Alcohol is one of the most common beverages in everyday life, but among the many liquor suppliers, how can a brand truly stand out?

+86 13602308576

cy@huanlianauto.com

No. 7 Yinhu Road, Sangyuan Industrial Park, Dongcheng Street, Dongguan City, Guangdong Province, China

Guangdong Huanlian intelligent Packaging Group Co., LTD

WhatsApp us

Send us a message if you have any questions or request a quote. We will be back catalog and price list to you ASAP!

Your project will meet a right solution with UBL.